How to measure your vent covers

A: In order to properly measure your vent covers, it is important to understand that it is the duct work opening that kul grille sizing is based on.

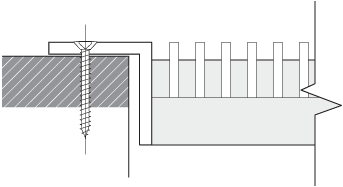

If you measure the length and width of your duct opening (e.g. 10"x3") you would order a 10"x3" kul grille. Our vent covers are manufactured slightly undersized to ensure a proper friction fit and compensate for any duct work or floor opening craftsmanship variances. The portion of the vent cover that inserts into the duct work is the “stack” which represents the order size. 1. Remove existing grille 2. Measure the hole Tip: Do NOT measure the old air vent cover. Every grille has a different size of outside frame so we cannot use the old/existing vent cover as a guide Tip: For custom sizes, please send us the exact dimensions of the hole. This helps us determine which size works best. (do not undersize the dimensions) 3. Choose your kul grille size:

The overall vent cover face will be larger due to the air vent cover frame that extends 1” past the stack and rests on the floor or mounting surface. The frame is also 1” to cover rough openings for a clean final appearance.

How to Measure for Your Vent Covers

Hole Opening Dimensions

Choose this Grille Size

Inside Stack Dimensions

Overall Frame Dimensions

10" x 3"

10" x 3"

9 3/4" x 2 3/4"

11 3/4" x 4 3/4"

10" x 4"

10" x 4"

9 3/4" x 3 3/4"

11 3/4" x 5 3/4"

12" x 2.5"

12" x 2.5"

11 3/4" x 2 1/4"

13 3/4" x 4 1/4"

12" x 4"

12" x 4"

11 3/4" x 3 3/4"

13 3/4" x 5 3/4"

14" x 2.5"

14" x 2.5"

13 3/4" x 2 1/4"

15 3/4" x 4 1/4"

14" x 4"

14" x 4"

13 3/4" x 3 3/4"

15 3/4" x 5 3/4"

10" x 6"

10" x 6"

9 3/4" x 5 3/4"

11 3/4" x 7 3/4"

12" x 6"

12" x 6"

11 3/4" x 5 3/4"

13 3/4" x 7 3/4"

14" x 6"

14" x 6"

13 3/4" x 5 3/4"

15 3/4" x 7 3/4"

14" x 8"

14" x 8"

13 3/4" x 7 3/4"

15 3/4" x 9 3/4"

Example: for a 10" x 4" opening, your grille dimensions will be as shown;

kul grilles can be used for wall and ceiling application as well as traditional floor registers. In order to mount vent covers securely to the ceiling and sidewall, select "Yes" from the "Include Mounting Holes" drop down menu. Our air vent covers require mounting holes to ensure a secure fit to the wall or ceiling. It is important to understand that our grilles recess into the desired location by 1” in depth. Overhead mounting of larger air vent covers is not recommended for safety reasons, unless mounted into a ceiling joist by a professional contractor. The purchaser is vulnerable to the risk of mounting screws not holding securely into a drywall surface overhead.

Mounting holes are required for a side wall and ceiling applications. In order to mount the air vent covers securely to the ceiling and sidewall, select "Yes" from the "Include Mounting Holes" drop down menu. They require mounting holes to ensure a secure fit to the wall or ceiling.

Mounting holes are not typically selected for a floor register applications unless the purchaser would like to secure the vent cover into the flooring surface. The mounting holes are counter sunk into the frame material to secure the air vent cover to the wall or ceiling so that once the mounting screw is installed into the mounting surface it is flush with the frame and clean in appearance. We recommend that wall and ceiling grilles be professionally installed. Fastening type: Countersunk screwholes Mounting hole dimensions Number of screws required for different grille sizes: Different sizes of grilles require a different number of holes/screws to ensure the air vent cover is properly secured into the ceiling / sidewall (the larger the grille, the more screws required to secure it to the wall or ceiling). The diagram below shows how many holes will be visible on each grille size and where they will be placed on the frame of the vent cover. Number of Screws: Screw Placement:

Countersunk screwholes are visible from the face of the vent cover and are required when mounting for sidewall and ceiling applications

Matching finish, flush mount screws provided with each order

Our kul grilles are made of high quality, extruded aluminum with mitered corners for a clean finished appearance. Our grilles have a fixed 1/4" spacing core with a 1" wide flange/frame and a 1" depth stack that recesses into the duct opening.

A: We have six finish options to choose from:

Black Monolith Anodized Light Bronze

Glacier Frost

Glacier Frost is a warmer shade of white. It is ideal for ceiling and wall applications but can also work for floor register applications. This finish can either be used to blend in or stand out depending on your design preference. We also offer a custom prime coat white option that can be painted any color on site.

Brushed Chrome

Brushed Chrome is a hand brushed sanded aluminum finish that has a stainless steel appearance with a light clear gloss protective finish. This is our most popular finish and looks great in any modern home design. It is especially effective when trying to match brushed hardware.

Black Monolith is a pitch black, matte powder coated finish that can either be used to compliment existing black finishes or to stand out on lighter applications.

Anodized Clear

Anodized Clear is a soft, matte metallic finish. Anodized coatings are intended to match other anodized features such as door and window frames. They are not highly recommended for high traffic floor register applications as the aluminum will scratch over time.

Anodized Light Bronze is a warm, bronze metallic finish. This finish compliments warmer tones and accents brown features while still providing a modern appearance. They are not highly recommended for high traffic floor applications as the aluminum will scratch over time.

Wenge Brown

Wenge Brown is a very dark commercial brown powder coated finish that can either be used to compliment existing brown finishes or to stand out on lighter applications. It is a very deep dark brown... almost black finish.

Brushed Chrome has the look of brushed metal (as the name implies). The finishing process consists of raw aluminum being carefully brushed and slightly buffed to create a linear metallic finish across the face of the grille. The grilles are then finished with a clear gloss coat as an extra layer of protection against scratching and general wear and tear, Brushed Chrome has a darker, more industrial look in comparison to Anodized Clear.

Anodized products have a metallic, almost iridescent or satin look. Clear anodized is no exception. Clear anodized has a soft, satin finish that leaves the grille looking very clean and fresh. Below is a photo of two grilles side by side (note they are slightly different sizes), showing the difference between brushed chrome (on the left) and anodized clear (on the right). You can see how they both have a nice, reflective surface but the brushed chrome offers a more textured, semi-gloss appearance while the clear anodized has a more consistent, matte satin look. If you are looking for advice on which finish to choose, we would have to say it comes down to personal preference. Anodizing increases resistance to corrosion but is a little more susceptible to scratching because of the finishing process. The brushed chrome is slightly more durable, and can withstand more traffic. From a purely looks perspective, they both look fantastic. We think that you will be very happy with either choice!

We do have the capabilities to custom powder coat prime our air vent covers to be paintable. We typically require a 10-grille minimum due to manufacturing setup fees, administrative fees and customization.

For more information regarding custom grilles please contact support@kulgrilles.com

Our standard vent covers have fixed cores to maintain a minimalist appearance and do not adjust or move. We do not ship out standard vent covers with dampers (maximum airflow is important, so we only provide dampers on request where airflow control is required). We have two damper options available. For additional information click here or contact our Sales Specialists at support@kulgrilles.com

Prior to ordering from kül grilles, please ensure you have reviewed our Technical Specifications document with your HVAC professional/contractor to confirm that our air vent covers will work properly for your air flow requirements. Click here to view our Technical Specifications